Product code: TRS-100 / TIK-200 / TIK-300 / TIK-400 / TIK-600 / TIK-800

+ PRODUCT DESCRIPTION:

Oilers TOP ROLL

TRS-100 / TIK-200 / TIK-300 / TIK-400 / TIK-600 / TIK-800

The Top Roll is a roller lube device that applies processing oil to the material being processed by the press machine.

Using top and bottom oiling rollers allows for uniform oiling on both the top and bottom surfaces of the material.

The amount of oil supplied to the oiling rollers can be easily adjusted by the flow control valve (cock).

The compact design makes it easy to install on press machines, die sets, etc. The TRS type can be installed using the mounting holes of the air feeder.

Specifications

TRS type equipped with an oil tank (gravity drop type)

| Model | Max. Material Width (mm) | Standard Oil Tank |

|---|---|---|

| TRS-100 | 100 (For AFE-40 to 100) | With 2 liter plastic tank |

For direct mounting to air feeder

TIK type equipped with an oil tank (gravity drop type)

| Model | Max. Material Width (mm) | Standard Oil Tank |

|---|---|---|

| TIK-200 | 200 | With 2 liter plastic tank |

| TIK-300 | 300 | With 2 liter plastic tank |

| TIK-400 | 400 | With 2 liter plastic tank |

| TIK-600 | 600 | With 2 liter plastic tank |

| TIK-800 | 800 | With 2 liter plastic tank |

General-purpose type for separate installation

Dimensions

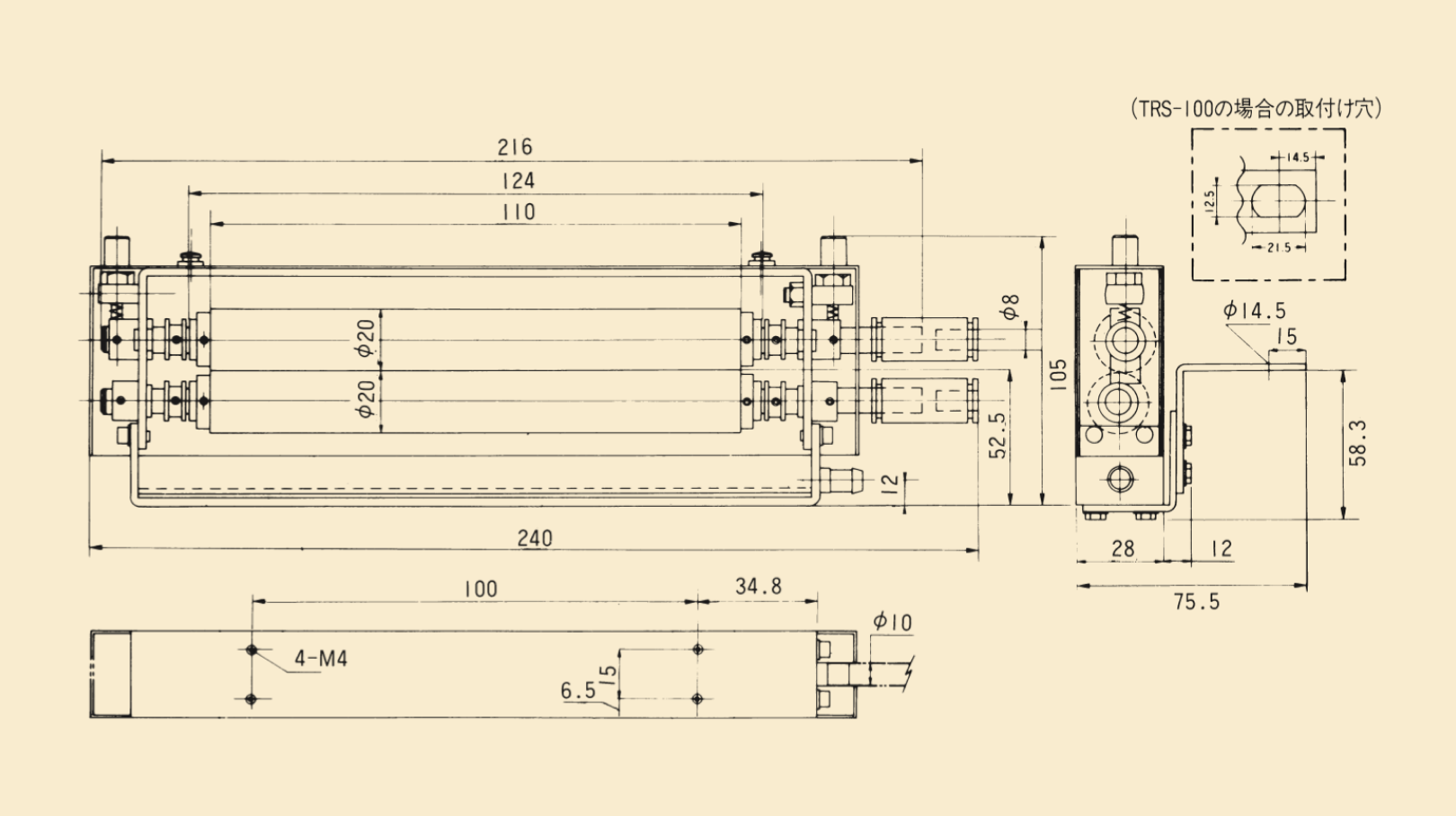

TRS-100

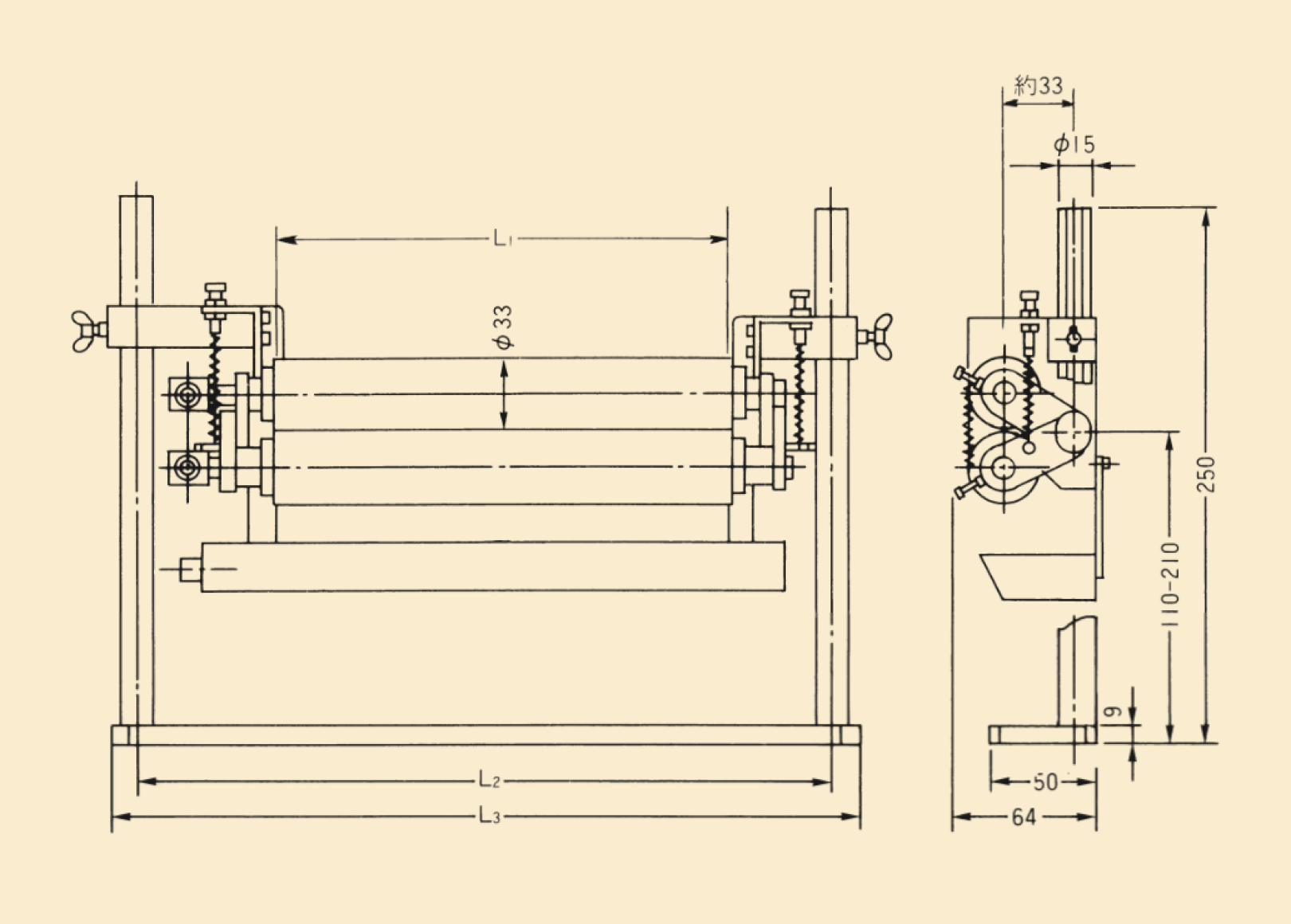

TIK TYPE

| Model/Dimensions | L1 | L2 | L3 |

|---|---|---|---|

| TIK-200 | 200 | 301.5 | 332 |

| TIK-300 | 300 | 406.5 | 437 |

| TIK-400 | 400 | 505.5 | 535 |

| TIK-600 | 600 | 709.5 | 740 |

| TIK-800 | 800 | 913.9 | 944 |

*. Depending on the viscosity of the oil you are using, it may not be possible to obtain a sufficient supply by gravity.

*. If the width of the coil material is less than half (50%) of the oiling roller width, material friction is low and the oiling roller may not rotate.

*. Please select the model that matches the width of the coil material.

Unwinding Machines

AUTO TURNTABLE

AUTO TURNTABLE T Series

AUTO TURNTABLE TL Series

TRAVERSER TR-963

Machine vision inspection system...

NC Grip Feeders NCG65SA

Winding Machines

HORIZONTAL AUTOMATIC WINDER MHA...

HORIZONTAL AUTOMATIC WINDER MHA...

MULTI-LAYER SPIRAL REEL WINDER...